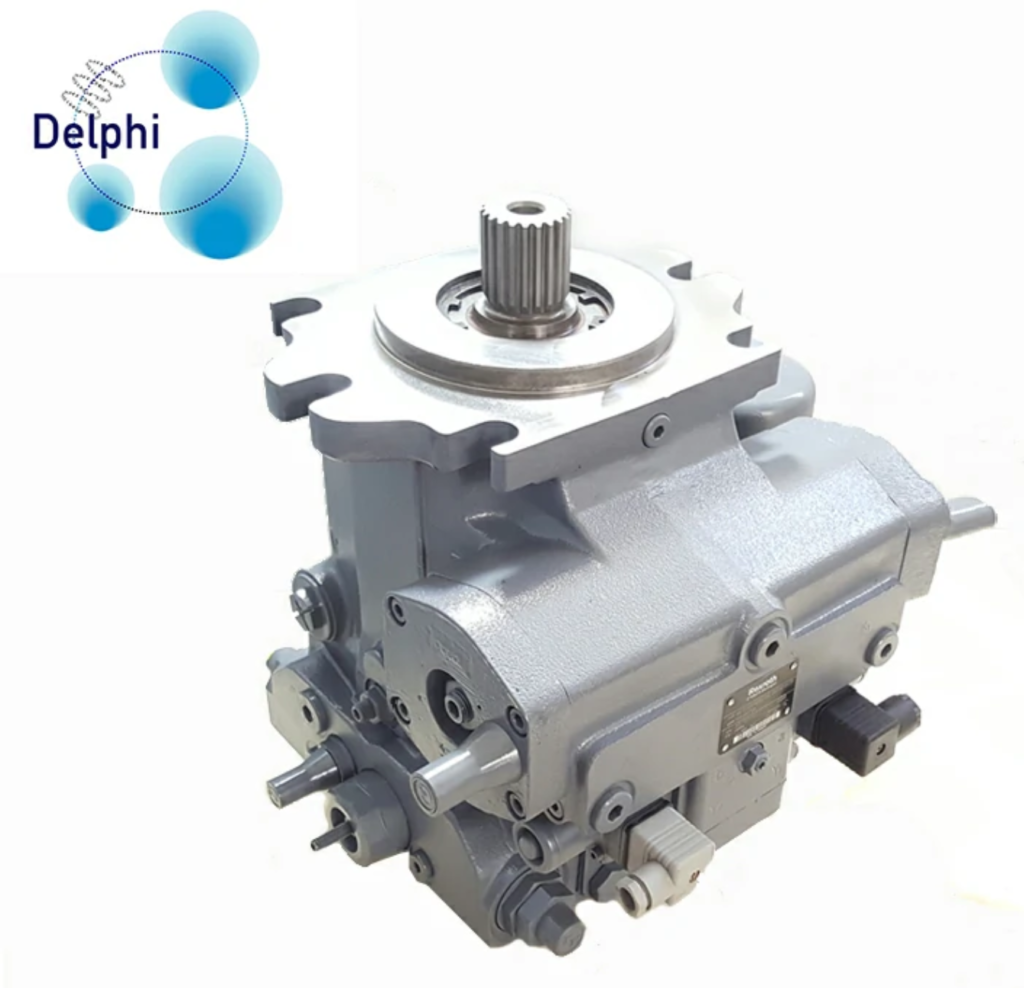

Hydraulic pumps are critical components in various industrial and mechanical applications. They convert mechanical power into hydraulic energy, facilitating the movement of fluids within a system. A hydraulic pump consists of several key components that work together to ensure efficient operation. For those looking to invest, considering a 2 pump hydraulic setup for sale can offer significant benefits.

Key Components of a Hydraulic Pump

1. Housing The housing encases the internal components of the hydraulic pump. It provides structural support and protection against external elements. Housing materials vary, including cast iron, aluminum, and steel.

2. Gears or Pistons Hydraulic pumps operate using gears or pistons. Gear pumps use rotating gears to move fluid, while piston pumps use reciprocating pistons. Both types have their own advantages depending on the application.

3. Drive Shaft The drive shaft connects the hydraulic pump to the power source. It transfers mechanical energy from the engine or motor to the pump’s internal components. The drive shaft’s efficiency directly impacts the pump’s performance.

4. Bearings Bearings support the drive shaft and reduce friction. They ensure smooth rotation and prolong the lifespan of the hydraulic pump. High-quality bearings are essential for maintaining optimal performance.

5. Seals and Gaskets Seals and gaskets prevent fluid leakage within the hydraulic pump. They ensure the internal pressure is maintained and the fluid flows efficiently. Regular inspection and replacement of seals and gaskets are crucial for preventing leaks.

Additional Components in a 2 Pump Hydraulic Setup

A 2 pump hydraulic setup for sale includes additional components to manage the dual pump system effectively. These setups are ideal for applications requiring high power and efficiency.

1. Hydraulic Reservoir The hydraulic reservoir stores the fluid used by the pumps. It ensures a continuous supply of fluid, maintaining system pressure and preventing air intake.

2. Filters Filters remove contaminants from the hydraulic fluid. Clean fluid is essential for the longevity and performance of the hydraulic pumps. Filters must be regularly checked and replaced as needed.

3. Valves Valves control the flow and direction of the hydraulic fluid. They regulate the pressure and ensure the fluid reaches the correct components. Valves are crucial for maintaining the efficiency of a 2 pump hydraulic system.

4. Accumulators Accumulators store excess hydraulic fluid and release it when needed. They help in managing pressure fluctuations and maintaining a consistent flow. Accumulators are especially useful in systems with varying demands.

Benefits of a 2 Pump Hydraulic Setup

Investing in a 2 pump hydraulic setup for sale offers numerous advantages. These setups provide higher efficiency and greater power output. They are suitable for applications requiring robust and reliable hydraulic systems. A 2 pump hydraulic supplier can offer expert advice on selecting the right setup for specific needs. They provide a range of options tailored to different industrial applications.

Choosing the Right 2 Pump Hydraulic Manufacturer

Selecting a reputable 2 pump hydraulic manufacturer is crucial. The quality of the pumps and components significantly impacts the system’s performance and longevity. A reliable manufacturer offers durable and efficient hydraulic pumps. They provide comprehensive support, including installation, maintenance, and troubleshooting. Working with a trusted 2 pump hydraulic supplier ensures access to high-quality products and expert guidance.

Maintenance of Hydraulic Pumps

Regular maintenance is essential for hydraulic pumps. It includes checking fluid levels, inspecting seals, and replacing worn components. Proper maintenance ensures the hydraulic pump operates efficiently and has a longer lifespan. Using quality parts from a reputable 2 pump hydraulic supplier enhances the reliability of the system.

Conclusion

A hydraulic pump consists of essential components such as housing, gears or pistons, drive shaft, bearings, and seals. In a 2 pump hydraulic setup, additional elements like reservoirs, filters, valves, and accumulators play vital roles. Investing in a 2 pump hydraulic setup for sale offers significant benefits, including enhanced efficiency and power. Choosing a reliable 2 pump hydraulic manufacturer and regular maintenance ensures optimal performance and longevity of the hydraulic system. With the right setup and support, hydraulic pumps can meet the demanding needs of various industrial applications.