Hydraulic pumps and motors are essential components in hydraulic systems. They work together to efficiently transfer power using pressurized fluids. In this blog post, we’ll explore how hydraulic pumps and motors work in simple terms so you can better understand these important pieces of machinery.

How Hydraulic Motors Work?

A hydraulic motor is essentially a hydraulic pump in reverse. Instead of converting mechanical energy to hydraulic energy, a hydraulic motor converts pressurized hydraulic fluid back into mechanical energy like torque and rotational motion.

Hydraulic motors use pressurized fluid to make their shaft rotate. As fluid enters one side of a hydraulic motor, it pushes against pistons or vanes, causing them to rotate. When the fluid exits on the other side, the pistons or vanes return to their starting position, continuing the cycle.

Different types of hydraulic motors include:

- Gear motors – Uses meshing gears rotated by the pressurized fluid.

- Vane motors – Utilizes vanes that rotate when fluid enters the motor cavity.

- Piston motors – Consists of pistons inside cylinders that are stroked by pressurized fluid to rotate the motor shaft.

The torque and rotational speed of a hydraulic motor is proportional to the pump’s pressure and flow rate. So by adjusting the pump’s displacement, you can control how fast and hard the hydraulic motor turns.

How Hydraulic Pumps Work?

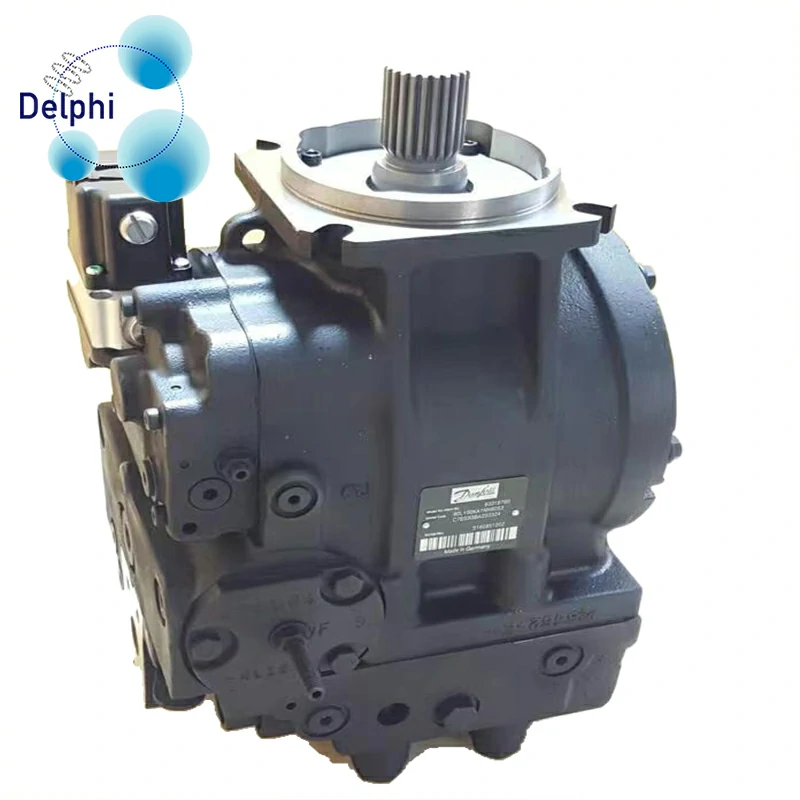

A hydraulic pump takes mechanical energy and converts it into hydraulic energy by pressurizing a fluid. Common types of hydraulic pumps include:

- Gear pumps – Uses meshing gears to move fluid. Simple design but lower pressure and efficiency.

- Kanatlı pompalar – Utilizes rotating vanes that press against a cam to push fluid. Handles higher pressures.

- Piston pumps – Consists of pistons inside cylinders that stroke to pump fluid. Provides precision and high pressures.

Most hydraulic pumps have a variable displacement design that allows the pump output – basınç, flow and power – to change based on the need. This makes hydraulic systems efficient.

When you turn the shaft on a hydraulic pump, it pressurizes the fluid inside and forces it into the lines that feed the hydraulic system. The higher the pump speed, the greater the fluid flow and pressure it produces.