Piston pumps play a crucial role in hydraulic systems. There are two main types: the axial piston pump and the radial piston pump. Each type has unique characteristics and specific applications. The axial piston variable pump offers particular advantages in control and efficiency.

What is an Axial Piston Pump?

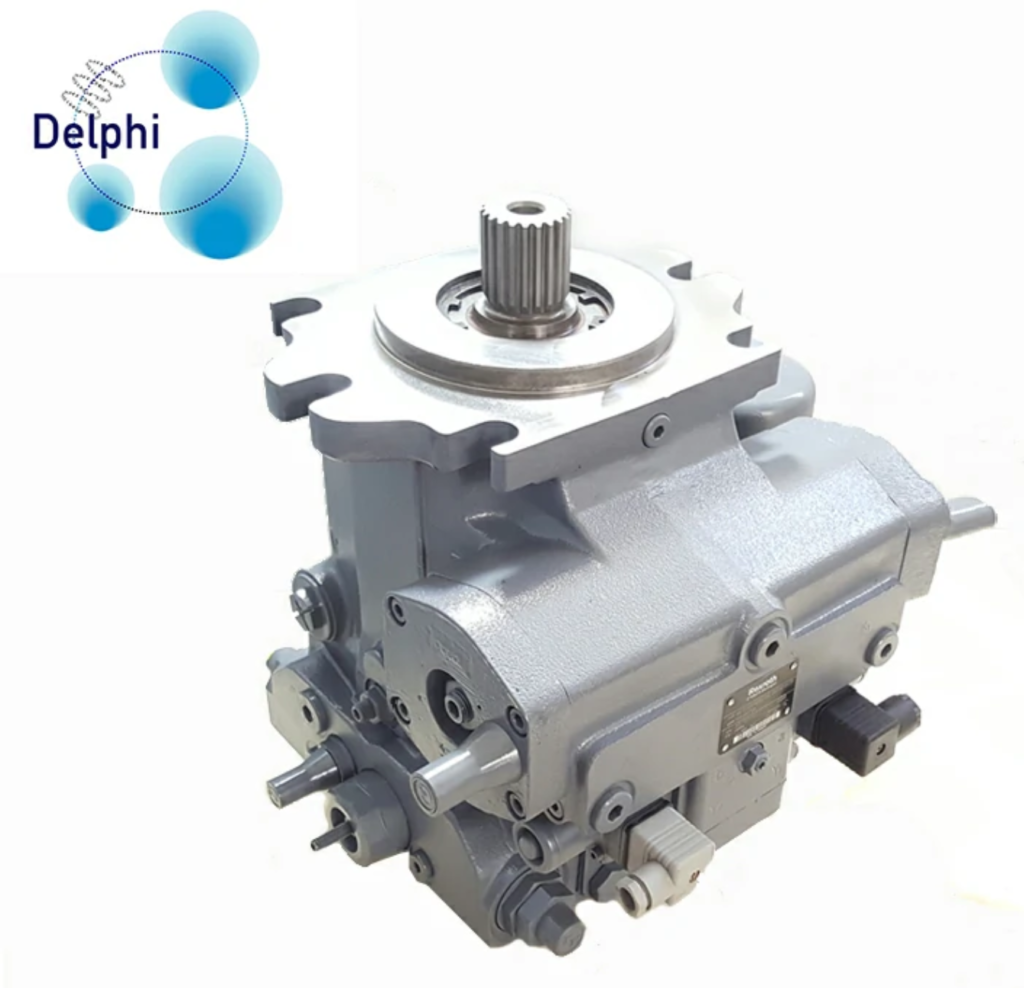

An pump has pistons arranged parallel to the drive shaft. These pistons move in and out to create fluid flow. This pump is known for its compact design and high efficiency.

What is a Radial Piston Pump?

A radial piston pump has pistons arranged perpendicularly to the drive shaft. The pistons move radially in and out, creating fluid flow. This pump type is typically larger and more robust.

Key Differences in Design

The main design difference lies in the piston arrangement. In this kind of поршневой насос, the pistons are aligned with the drive shaft. In a radial piston pump, the pistons are perpendicular to the drive shaft. This fundamental difference impacts the pump’s efficiency and application.

Efficiency and Performance

This pump typically offers higher efficiency. This pump design minimizes energy loss and delivers consistent performance. Radial piston pumps, while robust, may not match this efficiency level.

Applications and Uses

This is an ideal tool for high-pressure applications. You will find these pumps in heavy machinery, industrial systems, и аэрокосмические применения. Radial piston pumps are preferred for applications requiring high durability and robustness.

Variable Displacement in Axial Pumps

The axial piston variable pump allows for adjustable flow rates. This feature provides greater control and flexibility in hydraulic systems. Radial piston pumps generally do not offer this level of variability.

Maintenance and Durability

Both pump types require regular maintenance. Однако, radial piston pumps are often easier to maintain due to their simpler design. This kind of поршневой насос, though efficient, might need more specialized maintenance.

Cost Considerations

An axial piston pump can be more expensive due to its higher efficiency and complexity. Radial piston pumps, being simpler and more robust, may offer a cost advantage in some applications.

Choosing the Right Pump

Selecting between an axial piston pump and a radial piston pump depends on your specific needs. Consider factors such as pressure requirements, space constraints, and desired efficiency. The axial piston variable pump offers flexibility for systems requiring adjustable flow rates.

Installation Tips

Proper installation ensures optimal performance for both pump types. Secure all connections and follow manufacturer guidelines. Regular inspection helps maintain efficiency and prolongs pump life.

Environmental Impact

Both pump types can be environmentally friendly when used correctly. The axial piston pump‘s higher efficiency can reduce energy consumption. Radial piston pumps, with proper maintenance, can also offer long-term reliability.

Conclusion

Understanding the differences between an axial piston pump and a radial piston pump helps in making informed decisions. The pompa piston axial provides high efficiency and compact design, ideal for high-pressure applications. The axial piston variable pump offers added flexibility with adjustable flow rates. Choosing the right pump ensures optimal performance and meets specific application needs. Regular maintenance and proper installation further enhance pump longevity and efficiency