Hydraulic pumps convert mechanical energy into hydraulic energy. These pumps play a crucial role in many systems. They provide the necessary force for various applications. Moreover, they operate efficiently in different environments.

Types of Pumps

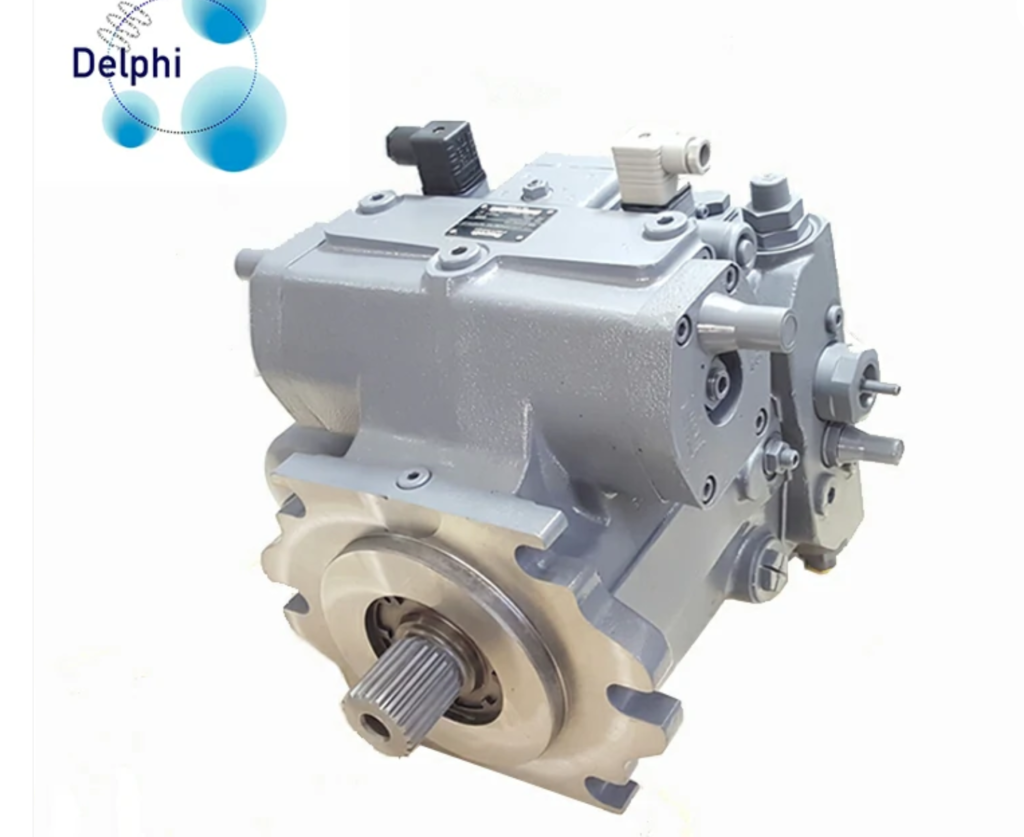

There are several types of pumps. Gear pumps, bombas de palhetas, and piston pumps are the most common. Each type has unique features and benefits. Por exemplo, gear pumps are simple and reliable. On the other hand, piston pumps offer high efficiency.

How Does it Work

These pumps work by creating a vacuum at the pump inlet. This vacuum draws fluid into the pump. Then, the pump forces the fluid through the outlet. O hydraulic pump motor powers this process. The motor converts electrical energy into mechanical energy. Adicionalmente, the motor’s performance affects the pump’s efficiency.

Lowrider Hydraulic Pumps

Lowrider hydraulic pumps are specific to lowrider vehicles. These pumps enable the vehicle to bounce and hop. They create the unique movements lowriders are famous for. Moreover, these pumps must be robust and reliable. Lowrider enthusiasts often customize these pumps. They ensure optimal performance and style.

Hydraulic Pump Components

Several components make up hydraulic pumps. The reservoir stores the hydraulic fluid. The pump itself moves the fluid. O hydraulic pump motor powers the pump. Valves control the flow and direction of the fluid. Filters keep the fluid clean. Hoses and fittings connect the components. Each part plays a critical role.

Applications of Hydraulic Pumps

These pumps have a wide range of applications. They power construction machinery like excavators and loaders. Industrial machinery also relies on them. Moreover, automotive systems use these pumps. Por exemplo, power steering systems depend on hydraulic pumps. Furthermore, aircraft use hydraulic pumps for various controls.

Maintenance and Care

Proper maintenance extends the life of the pumps. Regularly check the fluid levels and quality. Replace the hydraulic fluid as needed. Inspect the hydraulic pump motor for wear and tear. Ensure all components are clean and functional. Address any leaks immediately. Proper care ensures reliable performance.

Advantages

Hydraulic pumps offer several advantages. They provide high power density. This means they can generate a lot of force from a small unit. They also offer precise control. Adicionalmente, they operate smoothly and quietly. These benefits make them ideal for many applications.

Challenges and Solutions

Operating these pumps can present challenges. Por exemplo, leaks can occur. Regular maintenance can prevent this. Moreover, contamination can affect performance. Use high-quality filters to keep the fluid clean. O hydraulic pump motor can overheat. Ensure proper ventilation to avoid this issue.

Future

The future of hydraulic pumps looks promising. Advancements in technology improve efficiency and performance. Sustainable practices are becoming more common. Por exemplo, eco-friendly hydraulic fluids are now available. Adicionalmente, smart technology integrates with hydraulic systems. This enhances control and monitoring.

Conclusão

Hydraulic pumps are essential in various industries. They convert mechanical energy into hydraulic energy efficiently. Understanding the basics of these pumps is crucial. Different types, components, and applications highlight their versatility. Proper maintenance ensures their longevity. Despite challenges, advancements continue to improve their performance. Lowrider hydraulic pumps showcase their unique applications. O hydraulic pump motor remains a vital component. Hydraulic technology continues to evolve, promising a bright future.