The Rexroth Axial Piston pump and vane pump are essential in hydraulic systems. Both have unique features and applications. Understanding their differences helps in selecting the right pump. Each type offers specific advantages and challenges.

Basic Operation of Vane Pumps

Vane pumps use rotating vanes to move fluid. These vanes slide in and out of a rotor. As the rotor turns, the vanes create a vacuum. This vacuum draws fluid into the pump. The pump then moves the fluid through the system. Vane pumps are known for their simplicity. They provide consistent flow and pressure.

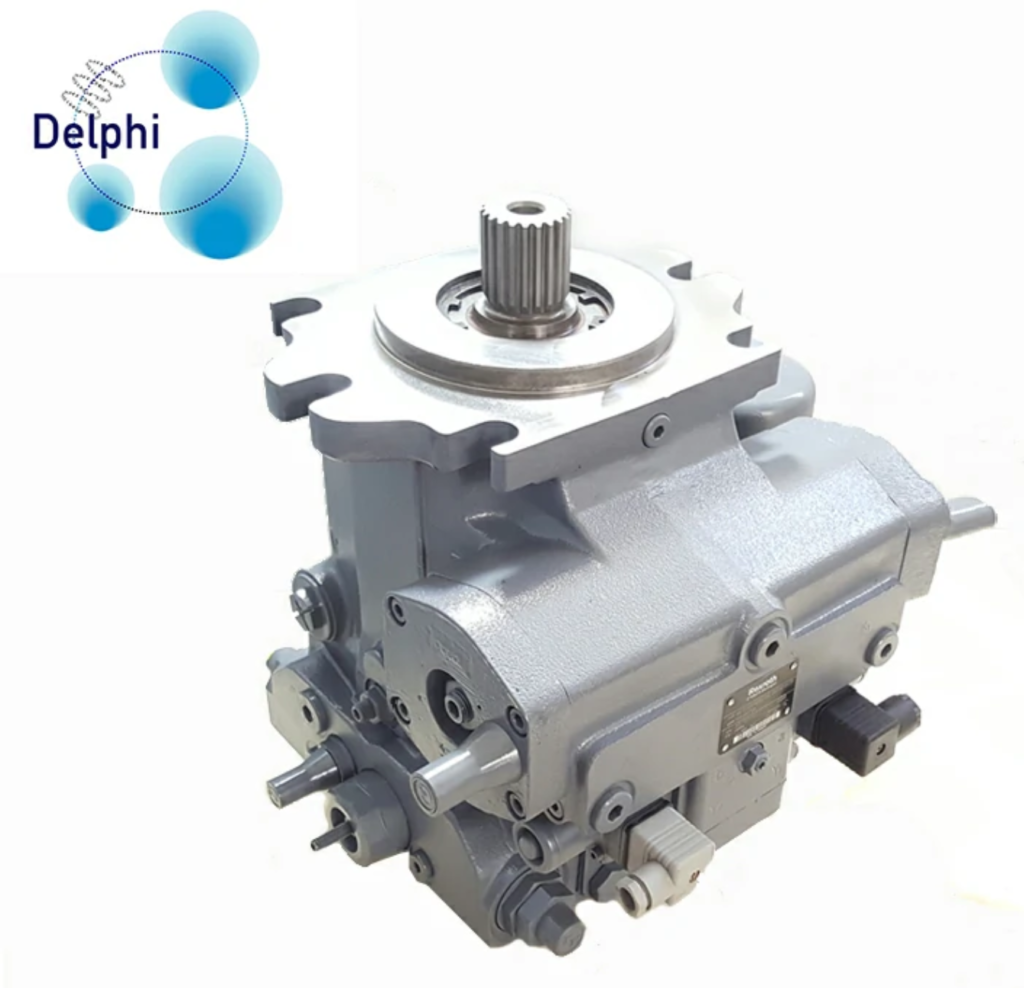

Features of Axial Piston Pumps

Rexroth Axial Piston pumps use pistons arranged in a cylinder block. These pistons move parallel to the drive shaft. The pump converts rotational energy into hydraulic energy. It achieves this through the movement of pistons. These pumps offer high efficiency and precision. They handle high pressures effectively.

Variable Pump A4Vso

The Variable Pump A4Vso is a type of axial piston pump. It allows for adjustable flow rates. This feature makes it versatile. Users can control the pump’s output according to their needs. This flexibility is beneficial in various applications. The Variable Pump A4Vso maintains efficiency under varying conditions.

Rexroth A11Vo Parts Manual

The Rexroth A11Vo Parts Manual provides detailed information. It helps in understanding the components of axial piston pumps. This manual assists in maintenance and troubleshooting. Knowing the parts ensures proper care and efficient operation. Regular reference to the manual prevents common issues.

Efficiency Comparison

Rexroth Axial Piston pumps generally offer higher efficiency. They handle higher pressures with minimal energy loss. Vane pumps, дегенмен, provide a steady flow at lower pressures. Efficiency varies based on the application and conditions. Both types serve different needs effectively.

Durability and Maintenance

Durability differs between the two pump types. Rexroth Axial Piston pumps are robust and long-lasting. They require precise maintenance. The Rexroth A11Vo Parts Manual is crucial for this. Vane pumps are simpler to maintain. Their design allows for easy replacement of parts.

Applications of Vane Pumps

Vane pumps excel in low-pressure applications. They are common in automotive systems. Power steering and air conditioning systems use vane pumps. Their steady flow and quiet operation are advantages. They are also used in small machinery and industrial applications.

Applications of Axial Piston Pumps

Rexroth Axial Piston pumps are ideal for high-pressure applications. Heavy machinery and industrial equipment rely on them. They are used in construction, mining, and marine industries. The Variable Pump A4Vso offers versatility in these fields. These pumps perform well under demanding conditions.

Cost Considerations

Cost is a factor in pump selection. Rexroth Axial Piston pumps tend to be more expensive. Their high efficiency and durability justify the cost. Vane pumps are more affordable. They are suitable for less demanding applications. Budget and requirements influence the choice.

Future Trends

Advancements continue in hydraulic pump technology. Rexroth Axial Piston pumps evolve with better efficiency and control. Sustainable and eco-friendly designs are emerging. Vane pumps also see improvements in materials and performance. Future trends focus on enhancing reliability and reducing environmental impact.

Conclusion

Understanding the differences between Rexroth Axial Piston and vane pumps is essential. Each type has unique features and benefits. The Variable Pump A4Vso offers versatility and control. The Rexroth A11Vo Parts Manual aids in maintenance. Efficiency, durability, and application guide the choice. Future advancements promise better performance and sustainability. Selecting the right pump depends on specific needs and conditions. Both types play crucial roles in various hydraulic systems.